Universal Safety Processes

Try these components as the core of your management system

Try these components as the core of your management system

As you consider a new management system or converting a traditional safety program to a management system, start by laying out the components or processes.

The safety profession makes available several safety standards for management systems. Standards can help you identify and design the components. The two most common standards are ISO 45001 and ANSI Z10. OSHA has a model. And several trade groups have developed industry-specific standards, such as mining and chemical processing. You can find, purchase, and download these standards for desk reference and planning.

Our founder began studying what makes an effective safety management system during 1995. He had a curiosity about the processes and practices organizations with low injury rates and insurance costs actually use to get their results.

Now we know. With data from over 500 organizations, we have captured a universal set of safety processes that comprise an effective management system, regardless of which safety standard an organization decides to follow, industry, or head count.

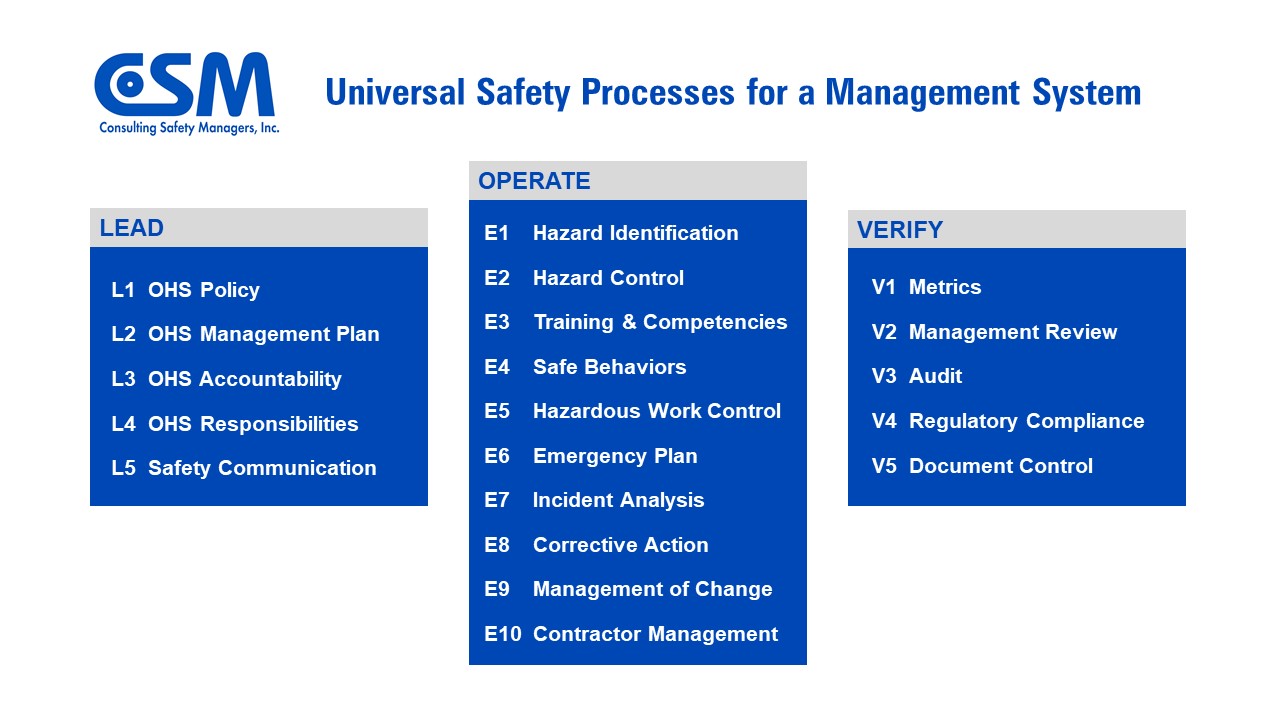

The universal safety processes we recommend and implement with organizations are above. The universal safety processes are categorized based upon their function: LEAD, OPERATE, and VERIFY.

Many organizations fall into a compliance trap with their management system. They get so focused on registration, conforming to a standard’s requirements, and generating paper evidence that they miss if the safety processes are truly functioning well and controlling risk. We see this pattern time after time.

Our value to organizations and their safety departments is we help them assure they are using an effective a set of universal safety processes.

Organizations and their safety departments partner with us to assure their universal safety processes are effective. We offer the following resources for each safety process and the entire set:

Contact us. We can help you master safety processes for your management system whether you have 20 employees or 2,000.

Consulting Safety Managers Inc. provides workplace safety solutions. SafeTask® is a registered trademark of Consulting Safety Managers, Inc. All rights reserved.

© 2021. Consulting Safety Managers,Inc.